Press Kit

Meatworks

287 State Rd.

Westport, MA 02790

774-319-5616

info@thelivestockinstitute.org

Fact Sheet

- Address: 287 State Rd, Westport, MA 02790

- Contacts: Keith Wilda

- Building Size: 11,000 sq ft

- Project Cost: $8.7 Million

- Number of Employees: 18

- Throughput Capacity: 5,000 Cattle Equivalents per Year

Our Mission

The mission of The Livestock Institute of Southern New England (or TLI) is to revitalize and strengthen livestock farming in Southern New England by (a) providing education and training to the community regarding humane and safe animal handling and slaughtering techniques, processing of meat, and related matters; (b) providing resources and information to the community regarding economic and agricultural development and management of resources; (c) offering job training for workers in small-scale, multi-species slaughterhouses and butchery; (d) conducting workshops and producing publications and materials to further the programs and educational concepts; (e) the creation of a state-of-art, USDA-inspected slaughterhouse and processing facility in Southeastern MA.

Who We Are

The Livestock Institute of Southern New England is a 501(c)(3) non-profit organization formed in early 2014 (formerly the Southeastern Mass. Livestock Association). The board of directors consists of livestock producers, food advocates, and agriculture supporters. The board members have diverse backgrounds including extensive work with start-up companies, real estate development and management, government work, local meat production, and food advocacy. The Board meets every other week, communicates regularly and oversees and manages all aspects of the educational programming and the slaughterhouse and processing facility.

Management

Meatworks Plant Manager (Bio coming soon.)

Our History

The need for a local animal processing facility was first identified in 2007 when Abreu’s Custom Slaughterhouse in Dartmouth closed. A small group of the producers, the Southeastern Massachusetts Meat Producers Association (SEMMPA), started work on finding a solution to the lack of slaughtering options in Southeastern MA. They examined a variety of alternatives including the type of facility (mobile, the conversion of an existing custom facility, or brick and mortar) that would best fit this area. Simultaneously, they moved forward with a survey of producers in Southeastern MA and concluded that building a new, small, brick and mortar USDA-inspected facility would be the best option to pursue. They also concluded that while a small, craft slaughterhouse could be profitable, the facility would need some public funding due to the prohibitively high cost of building a new state-of-the-art facility. In early 2014, the core group of producers formed the Southeastern Mass. Livestock Association (SEMALA), a Massachusetts non-profit, to be the vehicle to design, permit and build the facility.

In the processes of researching and designing a new slaughterhouse, it became apparent that without addressing the educational infrastructure for livestock farming and humane slaughter in Southern New England, the proposed slaughterhouse would not be successful. After much research and consideration, the SEMALA Board of Directors decided to pursue federal 501(c)(3) non-profit status with a strong educational mission.

In early 2016, SEMALA formally changed their name to The Livestock Institute of Southern New England (TLI), to reflect the new educational mission as well as to better reflect the target area for the organization. In early 2016, TLI hosted the first in a series of educational seminars on best practices for livestock farming. Since then TLI has grown its education programs to include a focus on business planning and strategy, along with providing resources for best practices in animal husbandry. TLI completed its third Livestock Conference at Bristol Aggie High School in late January 2019, that was well attended by over 120 people from our region.

In September 2018, TLI opened the doors to its Meatworks slaughter and processing facility.

In early 2019, TLI began collaborating with the University of Vermont, who received a major grant from the Cedar Tree Foundation of Boston. TLI will act as a subgrantee, representing CT, RI and MA in establishing the New England Grazing Network wherein TLI will be the coordinator for a variety of activities and educational opportunities in our three states to further Regenerative Grazing practices.

Scope

To date, Meatworks has provided processing services to over 700 local and regional producers from Massachusetts, Rhode Island, Connecticut, and New York.

- Species: Cattle, Veal, Hog, Sheep, Goat

- Further Processing: Patties, Linked, Bulk, and Smoked Sausages

- Curing/Smoking: Conventional and Naturally Cured Bacon and Ham

Testimonials

“Clean, humane, knowledgeable, and very friendly and accommodating to our fast pace beef and pork business. More retail cuts to market at our farmstand. The packaging and labeling are very professional, makes meats even more marketable which means more clients and more profit. Thank you for everything.”

– Ann Marie Bouthillette, Blackbird Farm, Smithfeld, RI

“I really appreciate this state-of-the-art facility and its accommodating staff. Trailering livestock has never been easier.”

– Suze Craig, Case Mill Farm, Westport, MA

“We are happy with the humane way our animals are handled, and our meat is always cut and packaged nicely.”

– Elizabeth Frary, Copicut Farms, Dartmouth, MA

“Working with individual farmers, the staff is totally engaged in high-quality customer service and humane treatment of the animals. They understand how important tracking animals through the facility is to ensure that every pound of my animal comes back with my farm name on it.”

– Ben Coerper, Wild Harmony Farm, Exeter, RI

“I’ve used six USDA-inspected facilities, and Meatworks tops them all with a state-of-the-art facility and tracking system, no stress animal handling, and people who care about my business and work with me to accommodate my needs.”

– Carter Wilkie, Little Compton, RI

Unique Selling Point

- Local

- Traceability, Tracking, and Yield/Inventory Reports

- High Food Safety Standards

- Humane Animal Handling

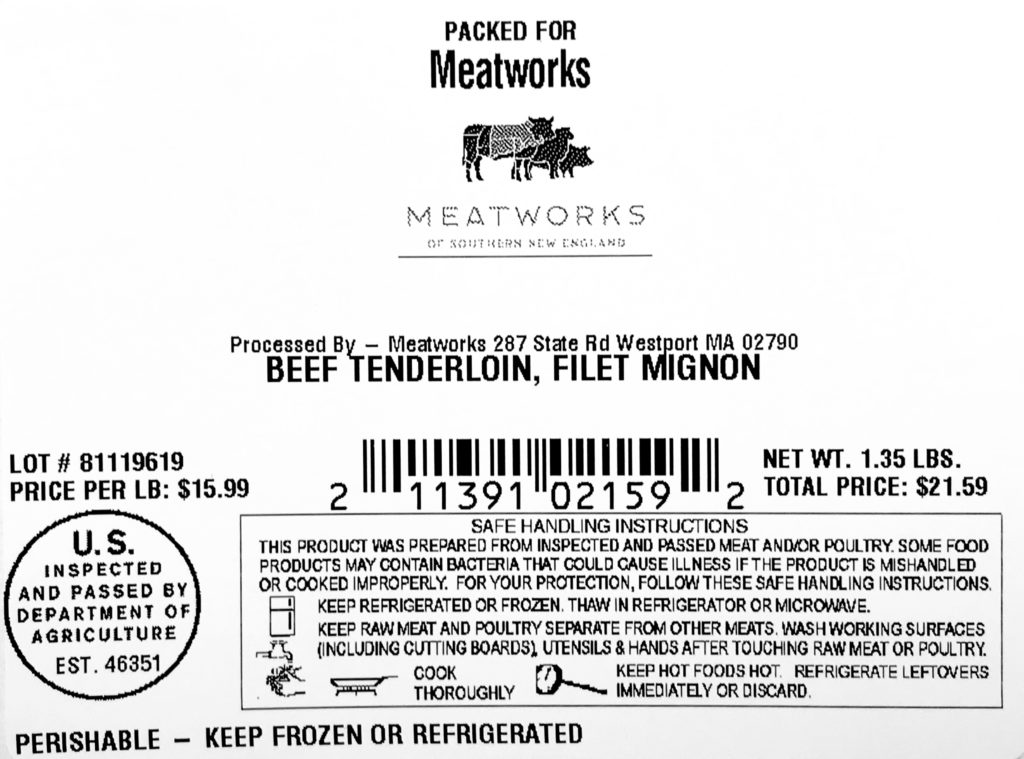

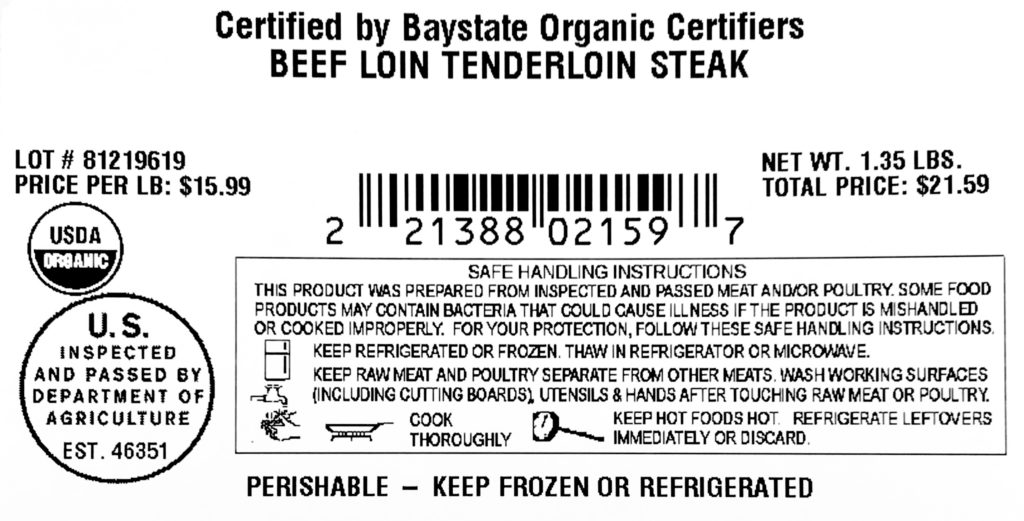

- Custom, Smart Labels

Meatworks has recognized the buy-local movement, and also the understanding of the importance of the provenance of food/meat. Meatworks is bringing the sophisticated capabilities of large plants to a local, small-scale through high quality, experienced management, providing additional services (yield and inventory data), state-of-art processing and tracking equipment, and highly professional presentation of meat thanks to experienced staff and state-of-the-art packaging equipment.

Customized Smart Labels provide producers with packages ready for the Point of Sale with cut name, weight, price, price-embedded UPC-A barcodes, ingredients, and lot#. Labels also include the USDA inspection seal, and USDA Organic, Animal Welfare Approved, Certified Grass-Fed, etc. seals as appropriate. Along with the labeled cuts delivered in boxes with master case labels, producers receive a yield report and a list of all cuts along with the weight of each. These data are really helpful when integrating with your point of sale, inventory tracking, and accounting software.

Meatworks in the Press

Humane Slaughter Needn’t Be an Oxymoron, Edible South Shore, 6/16/19, by Marek Kulig

https://www.ediblecommunities.com/stories/humane-slaughter-neednt-be-an-oxymoron/

Meatworks offers a new method, Country Folks, 6/10/19, by Laura Rodley

Livestock Institute opens retail meat shop at Meatworks, The Herald News, 2/25/19, by Kevin P. O’Connor

https://www.heraldnews.com/news/20190225/livestock-institute-opens-retail-meat-shop-at-meatworks

To Build A Better Slaughterhouse, Livestock Farmers Band Together In Westport, WBUR, 6/26/18, by Andrea Shea

https://www.wbur.org/bostonomix/2018/06/26/slaughterhouse-meatworks-more-humane-westport

Potential Story Ideas

- Producers, and Meatworks’ impact on them

- Employment opportunities/local economic impact

- Local food movement/access

- Temple Grandin designs/humane animal handling

- The Livestock Institute’s educational initiatives

- Sourcing locally raised meat for MA & RI schools

Photographs